Case studies

Optimise operational efficiency, lower OPEX, and step closer to your ESG goals with Juno.

BPA | pump optimisation and efficiency monitoring

Klarian is working with one of the UK’s foremost and most innovative onshore pipeline operators, British Pipeline Agency (BPA).

In 2022, BPA was grappling with rising operational costs due to the cost-of-living crisis that has seen energy prices soar. We’ve given BPA a deeper understanding of their pumping operations, enabling them to maximise efficiency and throughput while making significant energy and cost savings.

BPA want to increase efficiency and maximise throughput while slashing operational expenditure (OPEX) costs.

When we first spoke, BPA recognised the vast potential in their data, but it remained largely untapped. That’s why they turned to our big data and analytics capabilities, an integral part of our Juno service, to unearth hidden insights.

Our collaboration has illuminated BPA’s operations, providing them with a newfound depth of understanding. Armed with these insights, they are now empowered to fine-tune their operations.

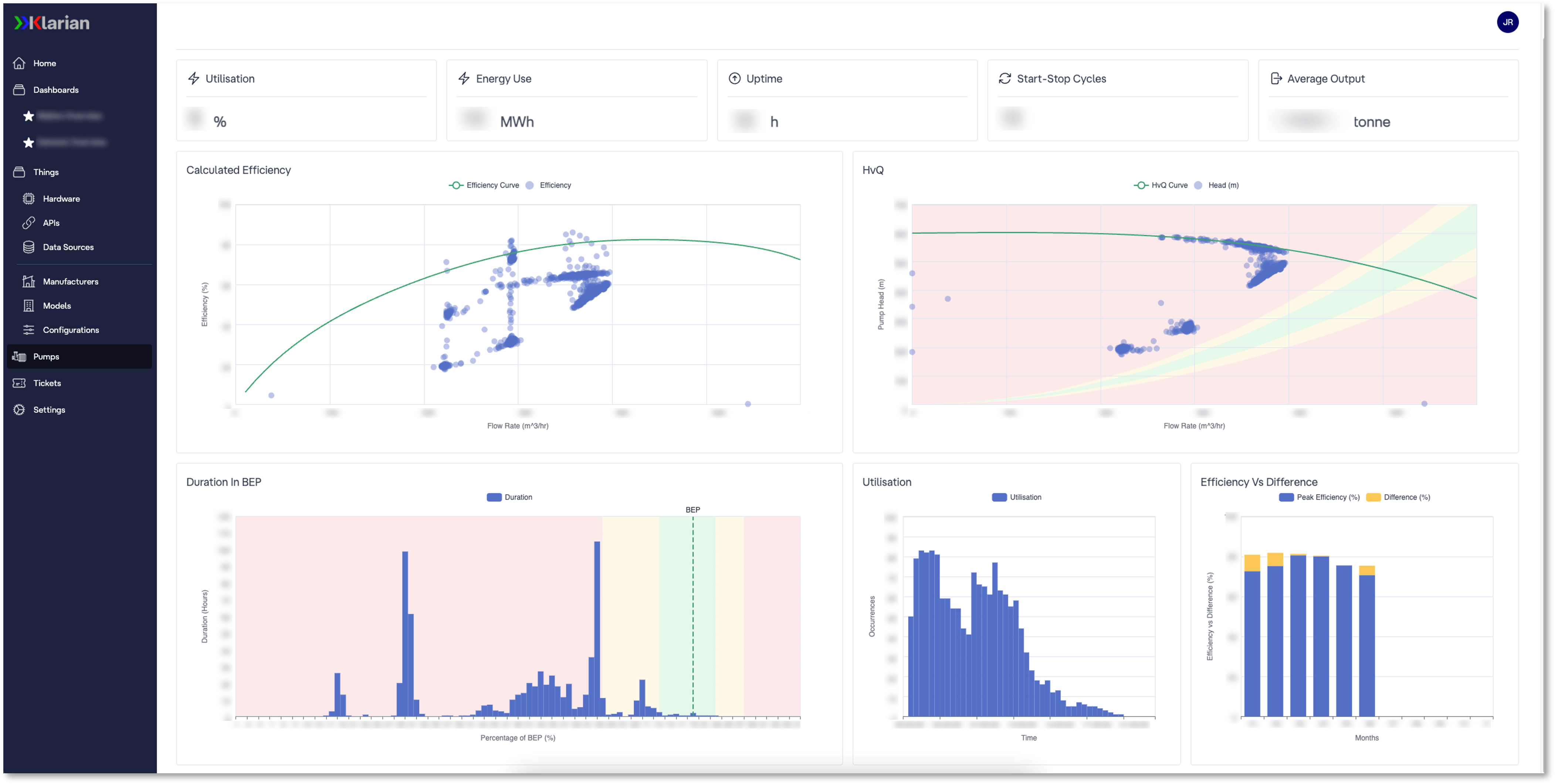

We began by investigating the pumping operations of a single-product jet fuel line supplying a major UK airport. Armed with SCADA data, our team analysed efficiency and pressure versus flow curves, system curves, energy costs, and peak efficiency points. Using virtual instrumentation and bespoke analytics models, we performed an exhaustive analysis for each pump.

Our analysis revealed several opportunities to boost the operational efficiency of this single pipeline. Since then, we’ve expanded our analysis to BPA’s wider network. As well as continuing our optimisation of BPA’s pumping operations, our current projects include developing analysis models for variable speed drive pumps, validation of drag-reducing-agents, routes analysis, machine health monitoring, and predictive maintenance.

Pumps are energy hungry machines. Our meticulous per-pump, per-route analysis revealed that BPA’s pump configurations were not operating optimally or energy efficiently. Our analysis uncovered various opportunities for BPA to fine-tune their pumps for optimal throughput, efficiency, and cost.

Optimal Routing

By pinpointing the most cost-effective routes for BPA to transport fuel from point A to B, Klarian has opened the door to precision scheduling and route optimisation for further efficiency gains:

On average, the potential energy savings of the optimal routes we identified was 18.8%.

In one instance, the potential energy saving reached as high as 69.2%.

Pumping Efficiency

Our analysis revealed that BPA’s average mainline pump would consume over £5,000 less energy each month if its efficiency were brought to as-new optimal levels. For booster pumps, this is almost an £8,000 monthly saving.

For BPA, we also identified a hydraulic throttling issue that, when fixed, will net BPA a saving of over £10,000 per month.

Here’s what John Armstrong, BPA’s CEO, has to say about our collaboration:

“Klarian has uncovered a number of areas where we can make significant efficiency gains and increases in throughput. We’ve already used their findings to justify key business decisions that will dramatically reduce our costs. We’re looking forward to seeing what else they reveal as we expand Juno across our network.”

We’re expanding Juno across BPA’s wider and more complex multi-product network. Our work will continue to guide their ongoing infrastructure investments and efforts to uphold uninterrupted operations.

DigipipeVision screenshot | pump efficiency.

Interested in learning more? Sign up and we’ll send you a free snapshot with more insight into our work with BPA.

UK Gas Pipeline Operator | Orifice Plate Quality Assurance

In 2023, Klarian embarked on a project with one of the UK’s leading gas pipeline operators.

The operator uses orifice plates for fiscal metering but had experienced incidents when orifice plates were returned incorrectly after calibration. In some cases, the mistakes went undetected for long periods of time. Recognising the financial impact of incorrect flow measurements, they tasked us with using our AI and big data capabilities to develop an anomaly detection solution. The goal was to identify when orifice plates were not functioning as intended. We developed mathematical and machine-learned models to detect anomalies quickly and, when applied across a gas system, provide confidence that equipment is operating as it should.

When it comes to orifice plates, precision is key. Any inaccuracies can result in incorrect flow rate measurements, which in turn can lead to a cascade of problems. These inaccuracies had the potential to cause errors in the operator’s billing or, more importantly, compromise the safety of their pipeline system. Over- or under-pressurising their system based on flawed measurements is a risk the operator couldn’t afford to take. What’s even more concerning is that, in certain instances, these faults lingered undetected for months, or even years, magnifying the risks. This is where anomaly detection comes into play.

Anomaly detection is crucial for identifying those rare events or observations that deviate significantly from normal data. In the context of orifice plates, detecting anomalies in flow rate data ensures safe, reliable, and cost-effective operations. Hence, why the operator chose to work with us.

So, how did we set about identifying whether the operator’s data points were normal or anomalous?

We began by analysing the operator’s standard operations and employing an AI module to create a system model for reference when assessing returned orifice plate performance. Comparing pre- and post-calibration with normal operations enabled straightforward anomaly detection.

We then set about studying the operator’s data using different mathematical techniques to identify the best approach for anomaly detection. The approaches we took included multivariate statistical analysis, artificial neural networks, and support vector machines.

Deploying our AI machine learning capabilities enabled us to evaluate each proposed method with different parameters – thresholds, batch sizes, and epochs. By comparing the results, we successfully identified anomalies, proving these approaches made for effective anomaly detection.

If orifice plates are reinstalled incorrectly, it can go undetected for years. By applying our anomaly detection solution powered by mathematics and AI, Juno Predict can successfully identify anomalies to lower the risk of costly installation mistakes going unnoticed.